JORSON manufacturers all our packing machines with top-grade components, ensuring the entire machine possesses superior quality. For the purpose of quality control, all of the machined components are strictly tested. Those components that have passed all tests are transported to our warehouse and await installation. All JORSON products are assembled by our skilled technicians. This provides a powerful guarantee on a high-precision assembly process.

Once the assembly process has been completed, all electrical control systems must be tested by our meticulous quality control inspectors. This process ensures all components of an electric circuit are properly connected and firmly fastened. We have also hired experienced and professional electricians who are responsible for the installation and testing of electrical systems. This multifunctional powder coating equipment performs a vital function as a core component that we are proud of, it is being adjusted. With the use of top-notch technology, it has been awarded 8 national patents. Prominent functions of this equipment include quick connection, wide adjustment range and many others.

This is our parts warehouse. Our equipment is made of top-grade components, guaranteeing the high quality of the entire equipment system.

German FESTO pneumatic parts

All the solenoid valves and pneumatic parts are products of the German brand FESTO.

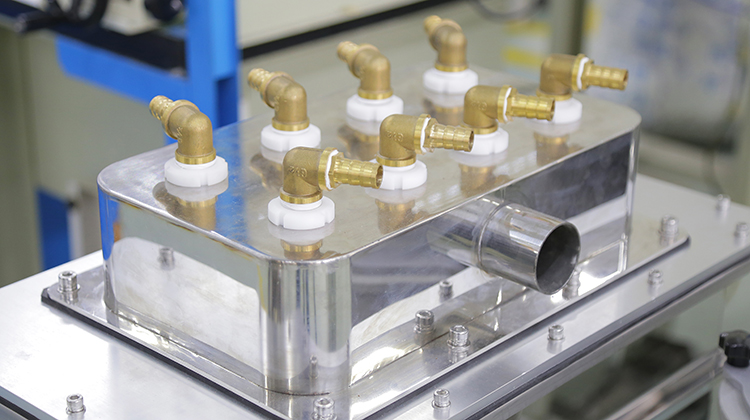

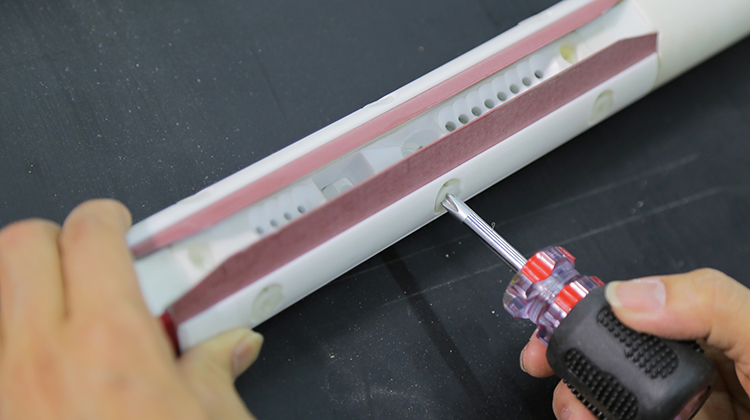

Assembly of powder recycling box

All JORSON products are assembled by our skilled technicians. This provides a strong guarantee on a high-precision assembly process.

The assembled backflush nozzle of the powder recycling box.

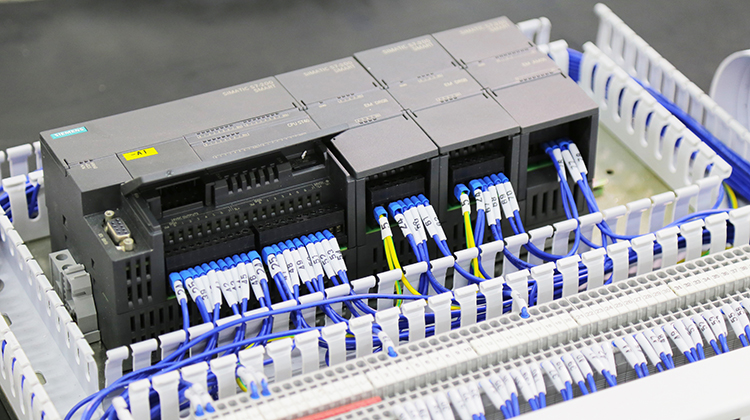

Once the assembly process has been completed, all electrical control systems must be tested by our meticulous quality control inspectors. This process ensures all components of an electric circuit are properly connected and firmly fastened.

The circuit control system has been installed and passed the tests.

The electrical system is installed and tested by experienced professional electricians.

Assembly area of powder coating machine for welding joint.

The powder coating machines for welding joints will be equipped with electrical systems.

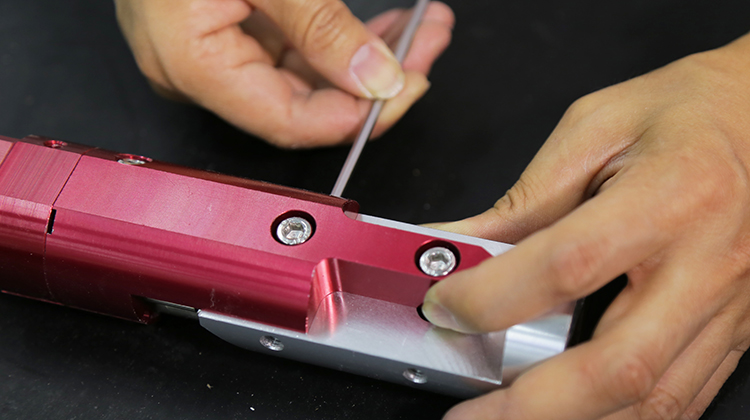

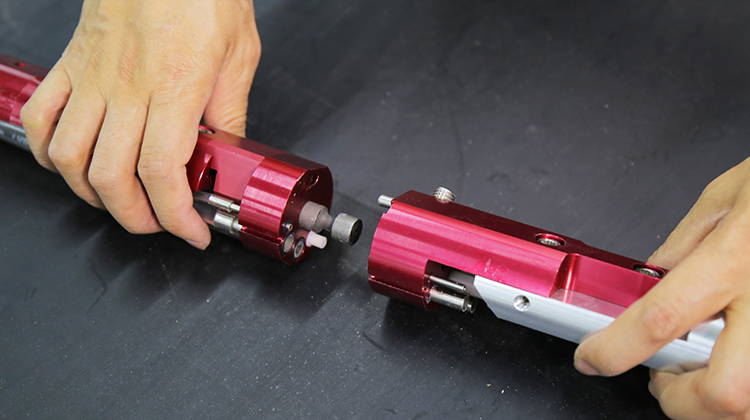

This multifunctional powder coating equipment performs a vital function as a core component that we are proud of, and here, it is being adjusted. With the use of top-notch technology, it has been awarded 8 national patents. Prominent functions of this equipment include a quick connection, wide adjustment range and more.

The manipulator is adjustable in both up and down directions.

The manipulator is adjustable in left and right directions.

The manipulator can move axially.

Quick connector for easy maintenance.

The width of the complement tape is steplessly adjustable.

The direction of powder coating is adjustable to get an even thickness of powder belt.

Suction on both sides prevents the powders from dropping.

JORSON TECHNOLOGY CO., LTD.

Headquarter: Building 15, innovation Science Park, Shilou Town, Panyu District, Guangzhou City, Guangdong Province, Chine, 511447

Factory: Plant B, No. 20, Lingxing Industrial Zone, Lianhuashan Bonded Industrial Zone, Shilou Town, Panyu District, Guangzhou City, Guangdong Province

Tel.: +86-20-38888996

Fax: +86-20-38886180

E-mail: info@jorson.com.cn